Parth Group

Engineering Excellence, Empowering Flow

Driven by innovation and backed by decades of expertise, Parth Group specializes in advanced flow control solutions through state-of-the-art manufacturing and fusion technologies.

Parth Poly Fusion

Stronger Flow Control Solution

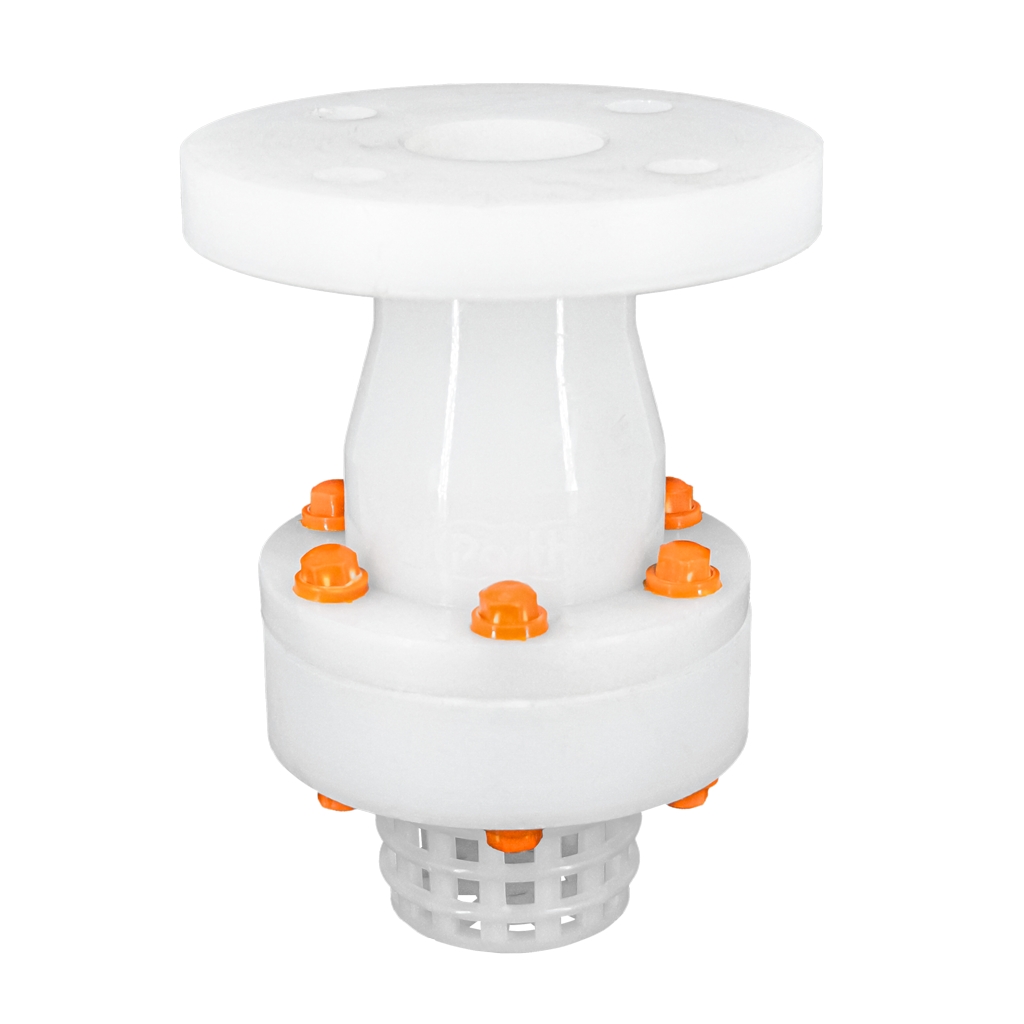

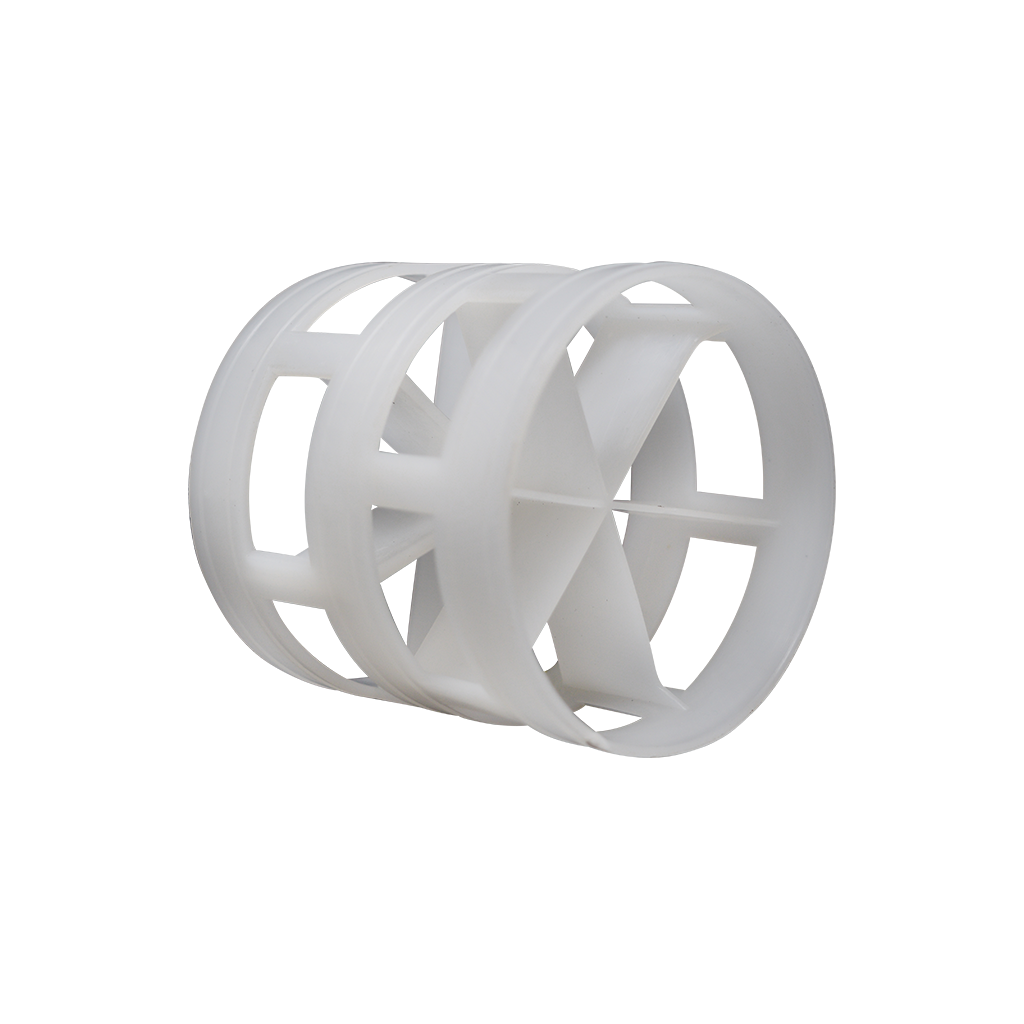

We specialize in manufacturing innovative and sustainable industrial flow-control solutions, including high-quality valves, pipes, fittings, and custom-engineered products.

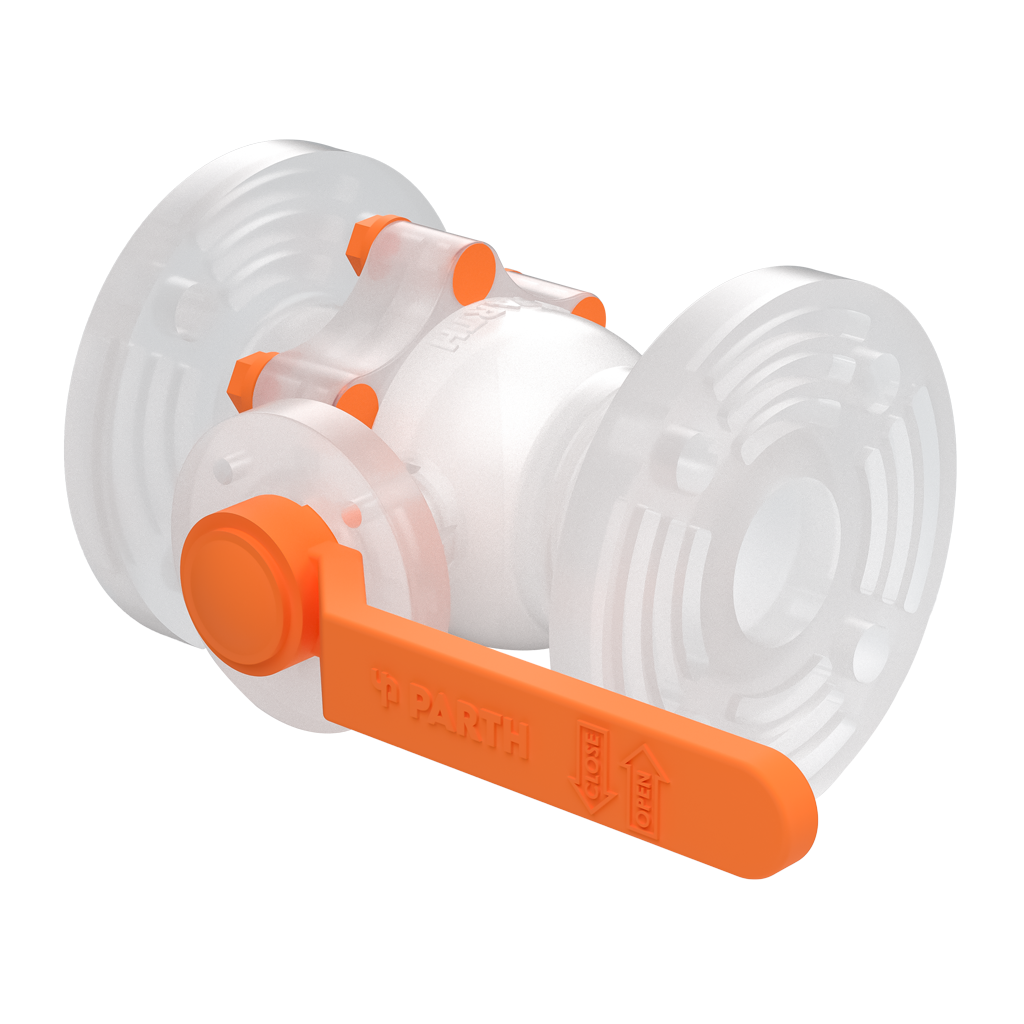

Parth Valves

Stronger, Reliable, and Precise

Designed for durability and efficiency, Parth Valves offer superior flow control, corrosion resistance, and high performance in demanding applications.

Parth Group

Engineering Excellence,

Empowering Flow

Driven by innovation and backed by decades of expertise, Parth Group specializes in advanced flow control solutions through state-of-the-art manufacturing and fusion technologies.

Parth Poly Fusion

Stronger Flow Control Solution

We specialize in manufacturing innovative and sustainable industrial flow-control solutions, including high-quality valves, pipes, fittings, and custom-engineered products.

Parth Valves

Stronger, Reliable, and Precise

Designed for durability and efficiency, Parth Valves offer superior flow control, corrosion resistance, and high performance in demanding applications.

WELCOME TO PARTH GROUP OF COMPANIES!

Manufacturing International-Quality

Flow Control Products.

Manufacturing International-Quality Flow Control Products.

Parth Group is a dynamic conglomerate led by its flagship company, Parth Poly Fusion Pvt. Ltd., comprising two key subsidiaries: Parth Poly Fusion Pvt. Ltd. (formerly Parth Poly Valves Pvt. Ltd.) and Aerochem Piping Pvt. Ltd.

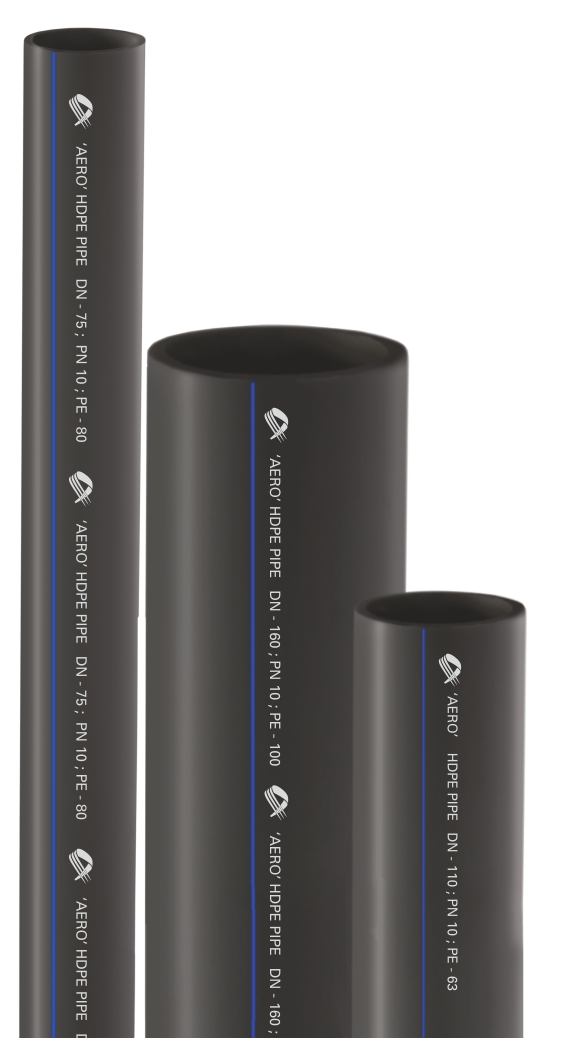

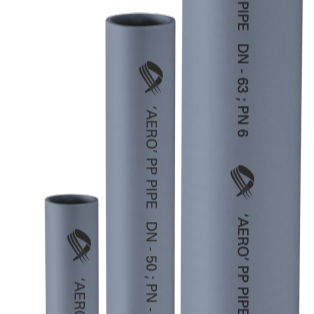

Parth Poly Fusion Pvt. Ltd. operates three brands—Parth Valves, Parth Fittings, and Parth Fusion (previously AURA)—offering high-quality flow-control solutions like anti-corrosive valves and fittings. Aerochem Piping Pvt. Ltd. supports this with Parth Pipes, delivering advanced piping systems for various industrial needs.

Our Objectives

Deliver Superior Quality

Expand with durable, advanced, and anti-corrosive flow-control solutions.

Drive R&D Excellence

Innovate sustainable, high-performance products meeting global standards.

Expand Global Presence

Strengthen partnerships and penetrate new markets as a trusted supplier.

Ensure Customer Satisfaction

Provide personalized service, timely delivery, and technical support.

Advance Fusion Technologies

Create effective solutions for evolving fusion needs.

Promote Eco-Innovation

Develop cutting-edge, sustainable technologies for a greener future.

Our Products

At Parth Group, we take pride in being a trusted name in the market, committed to delivering innovative, high-quality, and durable flow-control solutions. Explore our exceptional range of products designed to meet your needs!

Sustainability meets Innovation

Empowering industries for a greener future

At Parth Group, sustainability drives our innovation. We create advanced, eco-friendly flow-control solutions that ensure durability, conserve resources, and minimize environmental impact. We deliver high-quality valves, pipes, and fusion products through cutting-edge technology and exceptional service to support a greener future and empower industries worldwide.

We Uphold Excellence

At Parth Group, we follow industry-leading practices to deliver innovative flow-control solutions, driven by quality and advanced technology for a sustainable future.

- Innovative Solutions

- Sustainability Focus

- Customer-centric approach

- Global Standards

Our Journey

Don't Just Take Our Word For It

Testimonial

Ms. Payal Soni

B E Asia Pvt. Ltd.

Mr. Sagar

Bharati Hardware

Deccan Fine Chemicals(INDIA) Pvt. Ltd.

Mr. Shubham Patil

Parth Group consistently delivers excellent quality, great value for money, timely execution, and outstanding customer service- a truly recommendable company.

Outstanding service, timely execution, consistent quality- Parth Group is a trusted name for value-driven solutions.

From superior quality to timely fulfilment and consistent performance, Parth Group exceeds expectations every time.

Mr. Ashish

Mahek Enterprise

Mr. Kailas

Pune Techtrol Pvt. Ltd.

Shreeji Enterprise

Mr. Anand

Parth Group consistently delivers better products on time, with outstanding service and unbeatable value.

Really satisfied with the overall experience- great product quality, punctual delivery, and responsive support..

The execution was smooth, products were as expected, and their team was very helpful throughout.

Our clientele

Our Group Companies

“Parth” brand has built a strong reputation for delivering anti-corrosive, durable, & innovative products tailored to industries evolving needs worldwide through its group companies and sister companies.

Request a QuotE

Ready to work together? Build a project with us!

Learn More From

Frequently Asked Questions

What is electrofusion and how does it work?

Electrofusion is a method for joining polyethylene (PE) pipes using specialized fittings that have built-in electric heating elements. When an electric current is applied to the fitting, the embedded wire coils heat up and melt the inner surface of the fitting and the outer surface of the pipe. As the plastic cools, it solidifies into a robust, homogenous joint.

What are the advantages of using electrofusion fittings over traditional methods?

Electrofusion fittings offer several key advantages:

• Leak-proof joints due to precise control of the fusion process.

• Easy installation in tight or remote locations, as no open flames or large equipment are required.

• Reliable performance in high-pressure and buried applications.

• Traceability, since many fittings come with barcodes for automated parameter input and record-keeping.

Why should I choose thermoplastic valves instead of traditional metal valves?

Thermoplastic valves offer superior corrosion resistance, especially in applications involving aggressive chemicals, acids, or saltwater. Unlike metal valves, they do not rust or degrade in harsh environments, making them ideal for chemical processing, water treatment, and marine industries.

Are thermoplastic valves as durable and reliable as metal valves?

Yes, in many applications. Thermoplastic valves are lightweight yet strong, and they maintain excellent chemical and impact resistance. While they may not match metal in extreme temperature or high-pressure situations, they often outperform metal valves in terms of cost efficiency and longevity where corrosion or chemical compatibility is a concern.

What are the different fusion technologies and how do they work?

1. Electrofusion (EF)

How It Works: It uses special fittings with embedded electrical heating coils. An electric current heats the coils, melting the fitting and pipe surface to form a joint.

Key Features: Ideal for confined spaces and trench work, common in gas, water, and industrial piping, requires electrofusion control units (ECUs).

2. Butt Fusion (BF)

How It Works: Pipe ends are faced (planned) and heated against a hot plate, then pressed together. On cooling, they form a homogeneous joint.

Key Features: Fewer fittings required, best for large diameter pipes, requires skilled operators and machinery.

3. Socket Fusion (SF)

How It Works: Both the pipe and fitting are heated using a socket heating tool. Then pushed together manually to form a bond.

Key Features: Common for small diameter pipes (up to ~110mm), mostly used in residential plumbing, compressed air, and chemical transport. Simple and low-cost equipment. Quick for small, repeated installations.