Industrial Applications

Oil and Petroleum

construction sector

Water Supply

Nuclear Power plant

Gas Supply

Construction and Engineering

Pharmaceuticals

Textile and Cloth

Chemical and Fertilizers

Food Industry

Request a Quote

Learn More From

Frequently Asked Questions

What is electrofusion and how does it work?

Electrofusion is a method for joining polyethylene (PE) pipes using specialized fittings that have built-in electric heating elements. When an electric current is applied to the fitting, the embedded wire coils heat up and melt the inner surface of the fitting and the outer surface of the pipe. As the plastic cools, it solidifies into a robust, homogenous joint.

What are the advantages of using electrofusion fittings over traditional methods?

Electrofusion fittings offer several key advantages:

• Leak-proof joints due to precise control of the fusion process.

• Easy installation in tight or remote locations, as no open flames or large equipment are required.

• Reliable performance in high-pressure and buried applications.

• Traceability, since many fittings come with barcodes for automated parameter input and record-keeping.

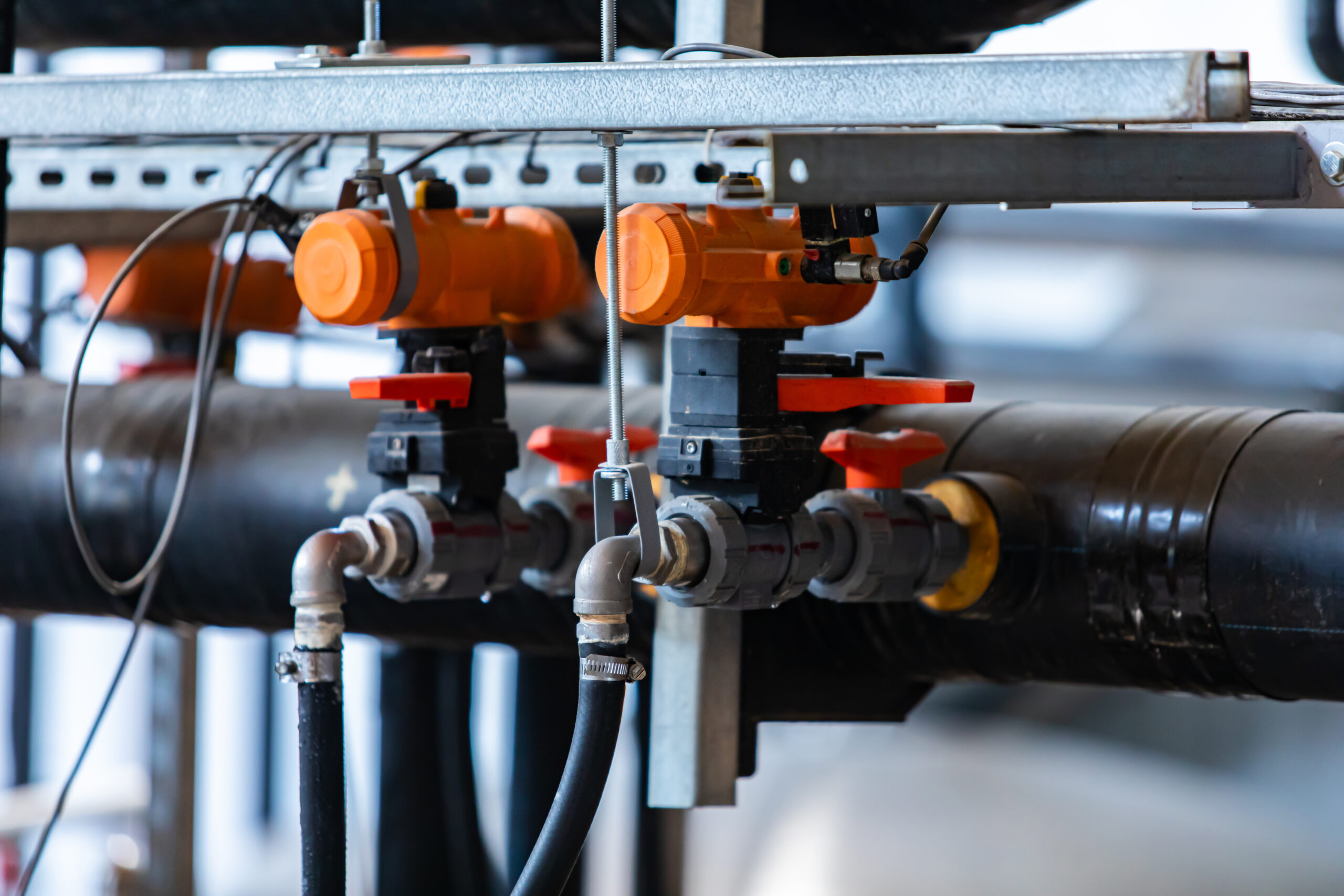

Why should I choose thermoplastic valves instead of traditional metal valves?

Thermoplastic valves offer superior corrosion resistance, especially in applications involving aggressive chemicals, acids, or saltwater. Unlike metal valves, they do not rust or degrade in harsh environments, making them ideal for chemical processing, water treatment, and marine industries.

Are thermoplastic valves as durable and reliable as metal valves?

Yes, in many applications. Thermoplastic valves are lightweight yet strong, and they maintain excellent chemical and impact resistance. While they may not match metal in extreme temperature or high-pressure situations, they often outperform metal valves in terms of cost efficiency and longevity where corrosion or chemical compatibility is a concern.

What are the different fusion technologies and how do they work?

1. Electrofusion (EF)

How It Works: It uses special fittings with embedded electrical heating coils. An electric current heats the coils, melting the fitting and pipe surface to form a joint.

Key Features: Ideal for confined spaces and trench work, common in gas, water, and industrial piping, requires electrofusion control units (ECUs).

2. Butt Fusion (BF)

How It Works: Pipe ends are faced (planned) and heated against a hot plate, then pressed together. On cooling, they form a homogeneous joint.

Key Features: Fewer fittings required, best for large diameter pipes, requires skilled operators and machinery.

3. Socket Fusion (SF)

How It Works: Both the pipe and fitting are heated using a socket heating tool. Then pushed together manually to form a bond.

Key Features: Common for small diameter pipes (up to ~110mm), mostly used in residential plumbing, compressed air, and chemical transport. Simple and low-cost equipment. Quick for small, repeated installations.

Sustainablity

Committed To Keep

People Healthy & Safe

At Parth Poly Fusion, sustainability means creating durable, eco-friendly solutions that minimize waste

and conserve resources. We are committed to protecting the environment while

delivering high-quality valves, pipes, and fittings for a better, greener future.