Join Our Team

Shape the Future with Parth Group

At Parth Group, we’re transforming the industry with advanced flow-control solutions.

Join a team that values creativity, collaboration, and a commitment to excellence.

Life at parth

Where Innovation Meets Opportunity

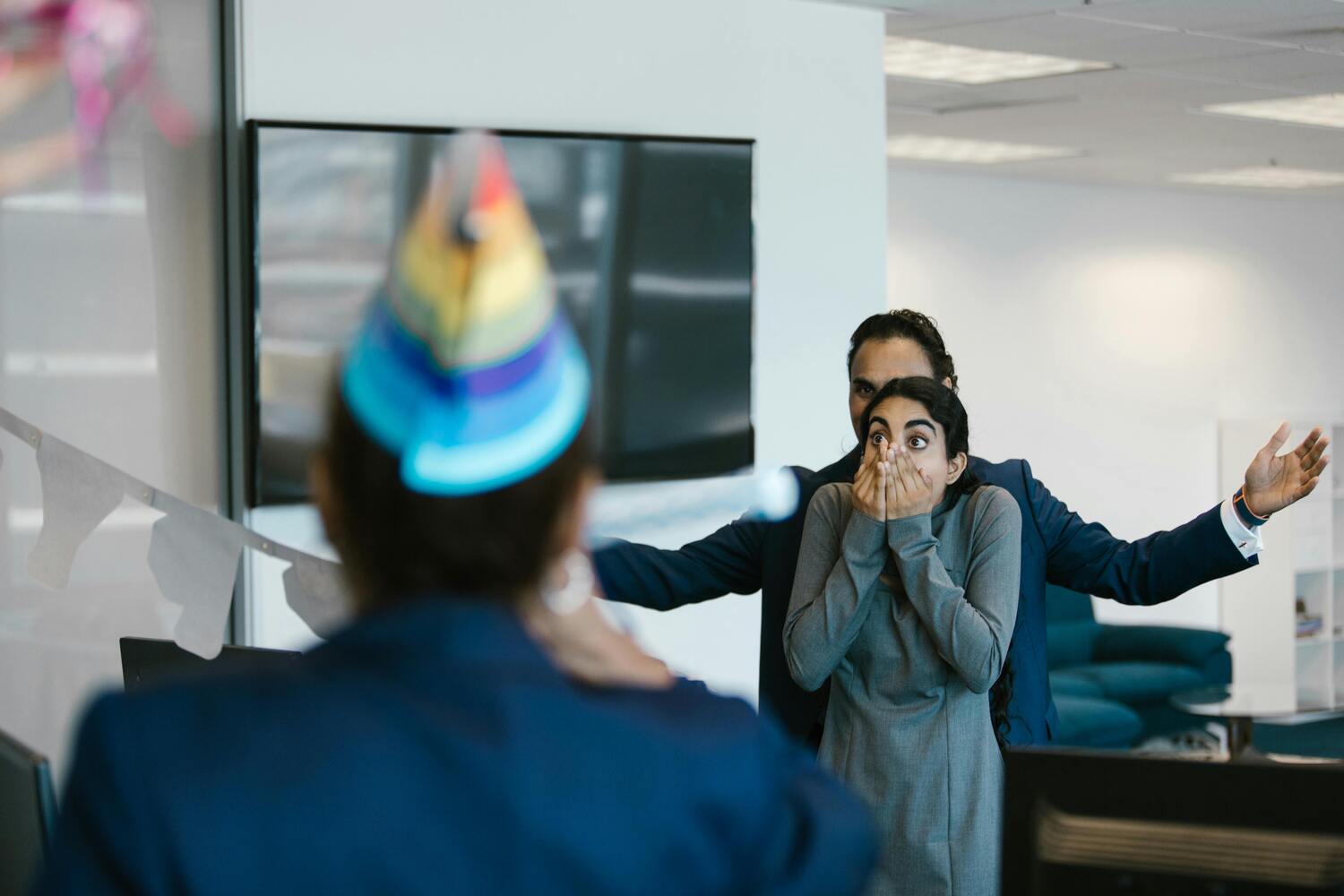

At Parth Poly Fusion, we believe in fostering a vibrant and inclusive workplace where every voice is valued. From collaborative projects to personal growth opportunities, we provide an environment that inspires innovation, celebrates achievements, and supports work-life balance.

- All

- Events

- Birthday Celebrations

- Festivals

Team Benefits

Why join Us

Innovative Work Environment

Be part of a future-focused company that embraces cutting-edge technology and continuous improvement.

Growth & Learning Opportunities

Enhance your skills through ongoing training, professional development, and exposure to global industry practices.

Supportive Team Culture

Collaborate with experienced professionals in a respectful, inclusive, and teamwork-driven environment.

Performance-Based Recognition

Your efforts are valued — we reward excellence, dedication, and innovation with meaningful recognition and advancement.

Job Stability & Legacy

Join a well-established organization with over three decades of industry leadership and consistent growth.

Commitment to Sustainability

Contribute to eco-friendly solutions and responsible practices that make a positive impact on industries and the environment.

Send Your Resume

Ready to work together? Send us your resume and contact details.

We will contact you soon.

Learn More From

Frequently Asked Questions

How can I apply for a job at Parth Group?

You can apply directly through our Careers page by submitting your resume and filling out the application form. You may also email your CV to our HR department at sales@parthvalves.com.

What qualities do you look for in a candidate?

We value candidates who are innovative, responsible, team-oriented, and eager to learn. A strong work ethic and a commitment to quality are essential.

Does Parth Group offer internship or training opportunities?

Yes, we offer internships and training programs for students and recent graduates looking to gain hands-on experience in the thermoplastic flow-control industry.

What is the interview process like?

Our process typically includes a resume screening, an initial HR interaction, followed by technical and/or managerial interviews, depending on the role.

Are there opportunities for career growth within the company?

Absolutely. We promote internal growth and offer clear career development paths, mentorship, and learning programs to help employees reach their full potential.