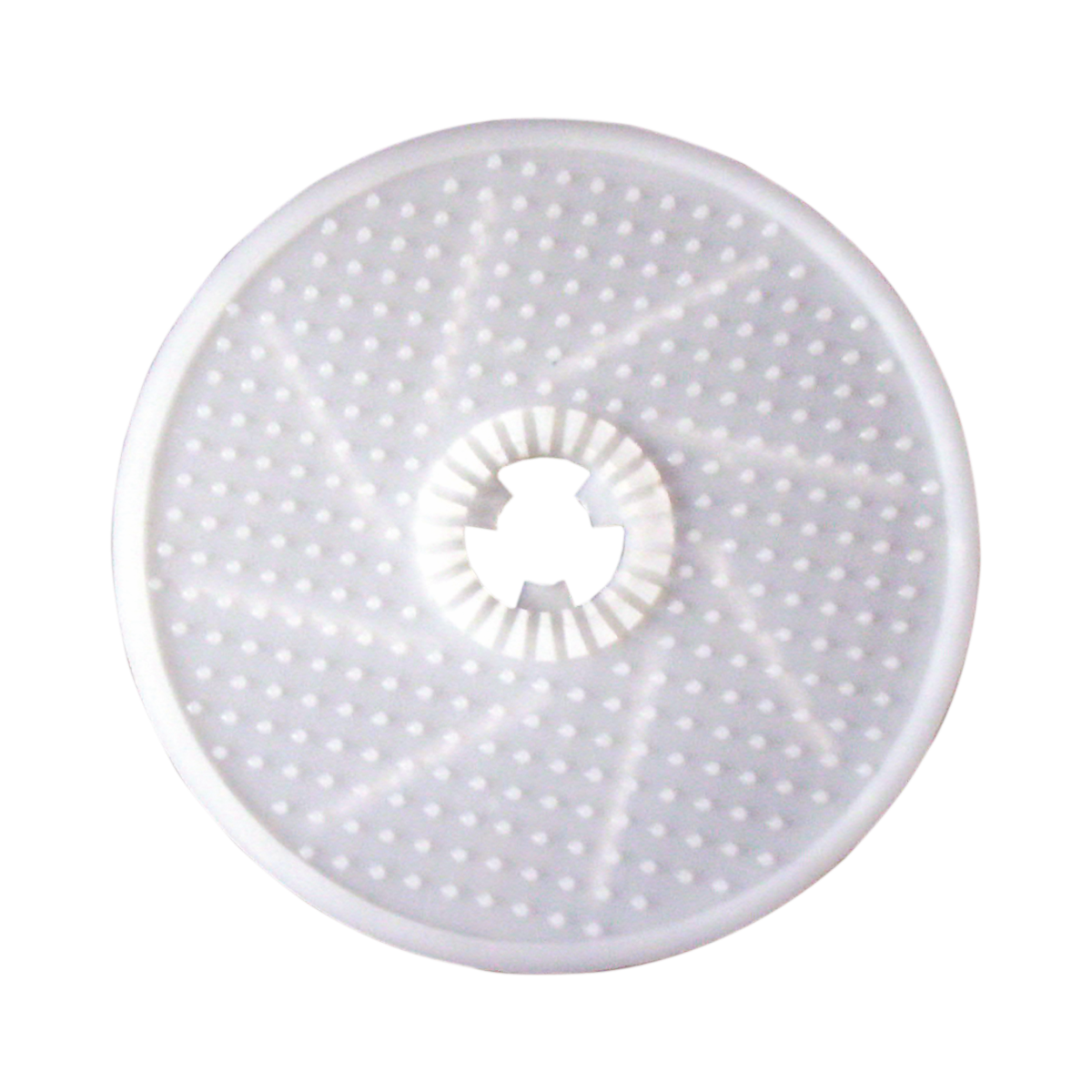

ELECTROPLATING FILTER PLATE

An electroplating filter plate is primarily used to remove solid particles, debris, and contaminants from the electroplating bath solution, ensuring the quality of the plating process by preventing impurities from affecting the final plated product; this is crucial in industries like automotive, aerospace, electronics, and jewelry manufacturing where high-quality plating is required.

Key points about electroplating filter plates:

Function: To filter out particles and contaminants from the plating solution, maintaining its purity and consistency for optimal plating results.

Material: Typically made from chemically resistant materials like polypropylene (PP) or polyvinylidene fluoride (PVDF) to withstand the corrosive nature of electroplating chemicals.

Application Areas:

- Metal finishing: Used in electroplating processes like chrome plating, nickel plating, copper plating, etc.

- Automotive industry: Filtering plating solutions for car parts like engine components, body panels, and hardware.

- Electronics manufacturing: Filtering plating solutions for printed circuit boards, connectors, and electronic components.

- Jewelry making: Filtering plating solutions for jewelry items to achieve a smooth and even finish.

MOC: P.P.C.P

Available Sizes: