Poly valves are an essential component in various industrial applications, playing a crucial role in controlling the flow of liquids and gases. Unlike traditional metal valves, poly valves are made using polymer-based materials, such as polyethylene, polypropylene, and other engineered plastics. This gives them a unique combination of strength, durability, flexibility, and resistance to corrosion and chemicals.

Advantages of Poly Valves

- Lightweight: Poly valves are significantly lighter than metal valves, making them easier to handle and install, thereby reducing transportation and labor costs. This also puts less strain on the piping infrastructure.

- Corrosion Resistance: One of the most significant benefits of poly valves is their high resistance to corrosion and chemical reactions with corrosive substances like acids, alkalis, and saltwater.

- Cost-Effectiveness: Poly valves are typically more affordable than metal valves in terms of manufacturing, installation, and maintenance. Their durability and reduced maintenance requirements contribute to long-term cost savings.

- Ease of Installation and Maintenance: Their lightweight nature simplifies installation, often requiring fewer tools and resources. Maintenance is also straightforward, typically involving routine inspection and cleaning.

- Sustainability: Many poly valves are made from recyclable materials and their long lifespan, thanks to corrosion resistance, contributes to minimizing waste.

Common Applications

Poly valves find use in a wide range of applications, including:

- Chemical Processing: Handling acids, bases, salts, petroleum products, and other chemicals.

- Water Treatment and Distribution: Controlling the flow of water in filters, chlorinators, and distribution networks. Polyethylene valves are commonly used for this purpose.

- Wastewater Treatment: Controlling the flow of wastewater and handling high temperatures and acidity.

- Irrigation and Agriculture: Managing water flow in irrigation systems, especially when fertilizers and chemicals are applied through the water.

- Food and Beverage Processing: Controlling fluid flow in various processes like bottling, packaging, and cooking.

- Pharmaceutical Industry: Drug manufacturing, delivery, and laboratory testing.

- Natural Gas Distribution: Controlling the flow of natural gas.

- Residential Plumbing: Main shutoffs and repairs.

- Other Industries: Oil and gas, automotive, HVAC systems, swimming pools, pharma, and chemical laboratories.

Types of Poly Valves

Several types of poly valves exist; each designed for specific applications:

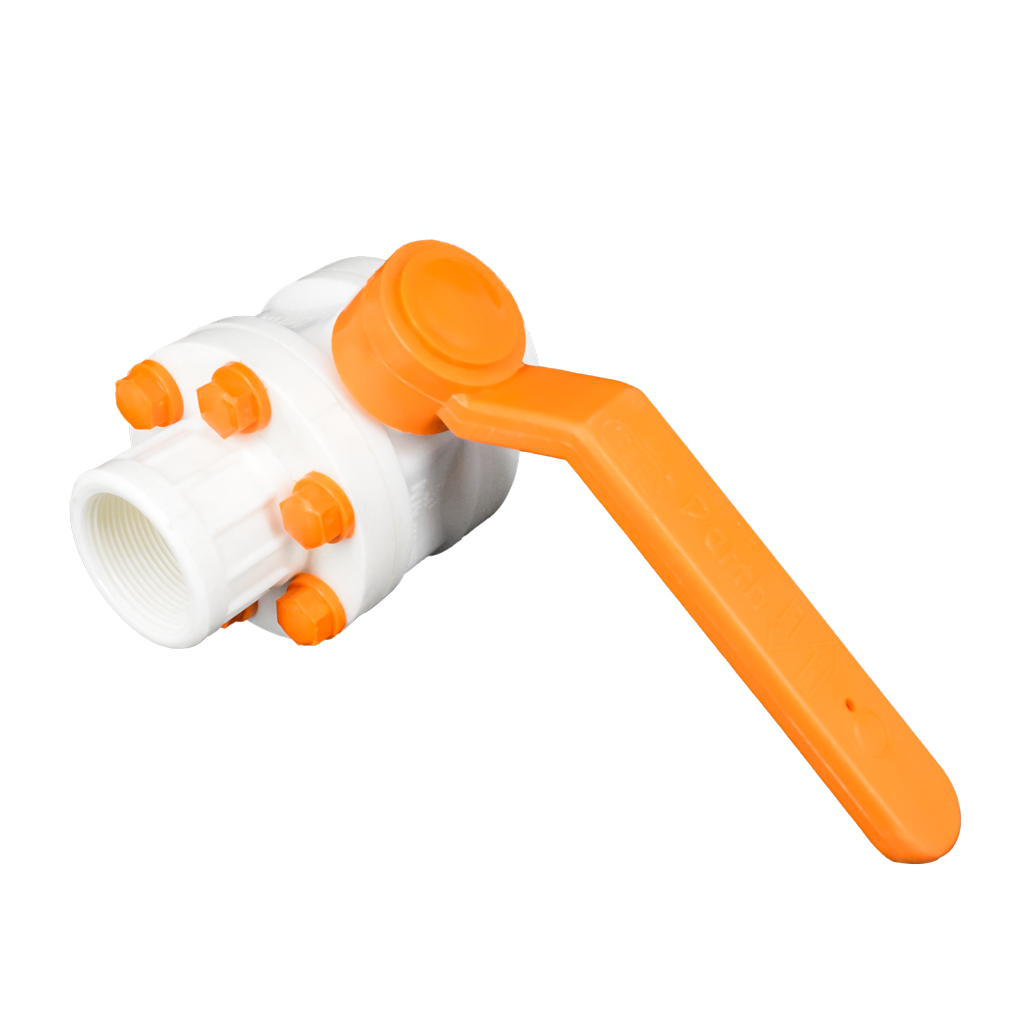

- Ball Valves: Widely used for reliable shut-off and quick, precise flow control.

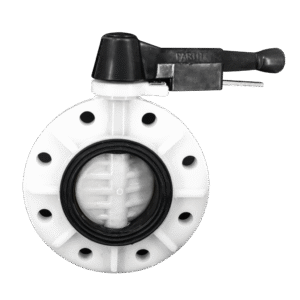

- Butterfly Valves: Suitable for applications requiring quick opening and closing and moderate flow regulation.

- Foot valves: Type of check valves typically used at the bottom of a suction pipe, often in pumping systems, to prevent backflow and maintain the pump’s prime. It allows fluid to flow in one direction (into the pump) but prevents it from flowing back out when the pump is not operating. This ensures the pump remains primed and ready to operate without needing to be re-primed each time, saving energy and preventing damage from running dry.

- Diaphragm Valves: Used in applications that require high levels of hygiene or purity, common in the pharmaceutical, food, and beverage industries.

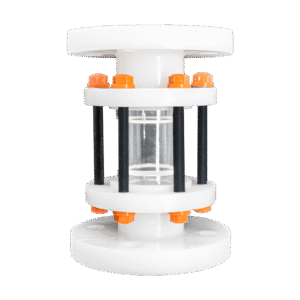

- Flow indicators: Particularly sight flow indicators, are visual devices installed in pipelines to confirm the presence, direction, and approximate rate of fluid or gas flow, as well as to observe fluid properties like color and clarity, finding extensive applications across various industries including oil & gas, pharmaceuticals, water treatment, food & beverage, and HVAC systems.

- Y-type strainers: Used to remove solid debris from liquid, gas, or steam pipelines, protecting downstream equipment from damage. They are commonly found in various industrial applications like oil and gas, power generation, and chemical processing.

Materials Used in Poly Valves

The polymer materials used in poly valves include:

- Polyethylene (PE): Offers excellent chemical and corrosion resistance, lightweight, and flexibility.

- Polypropylene (PP): Known for superior chemical resistance and higher temperature tolerance compared to PVC and CPVC, making it suitable for aggressive acids, alkalis, and corrosive media.

- Polyvinylidene Fluoride (PVDF): Provides good wear resistance and excellent chemical resistance, but its performance may be limited at elevated temperatures.

- PP-H: Polypropylene Homopolymer is a type of plastic known for its strength, rigidity, and chemical resistance. It’s often used in industrial applications like chemical processing, construction, and laboratory equipment due to its ability to withstand harsh environments and corrosive substances.

- Isotactic polypropylene (iPP): Semi-crystalline thermoplastic polymer with enhanced mechanical properties and a higher melting point compared to other types of polypropylene, like atactic PP. This regularity in structure results in high stiffness, rigidity, good chemical resistance, and a melting point generally between 160 °C and 180 °C.

Important Considerations When Choosing Poly Valves

- Material Compatibility: Ensure the valve material is compatible with the substances it will handle to avoid chemical reactions or degradation.

- Flow Rate Requirements: Select a valve with a capacity that matches your system’s flow rate to avoid inefficiencies or bottlenecks.

- Pressure and Temperature Conditions: Consider the operating pressure and temperature, as these factors can affect the valve’s durability and performance.

- Connection Type: Choose a valve with a connection method that aligns with your existing system (threaded, flanged, etc.) to simplify installation and maintenance.

- Industry Regulations and Standards: Ensure the chosen valve type complies with relevant industry regulations and certifications for safety and efficiency